Lee Valley Cast Scratch Stock

Lee Valley Cast Scratch Stock with beading, fluting and reeding cutters.

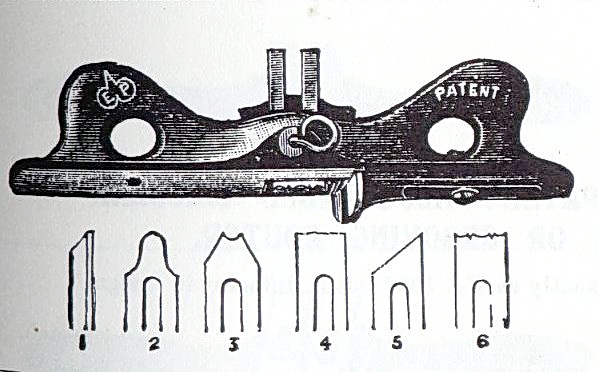

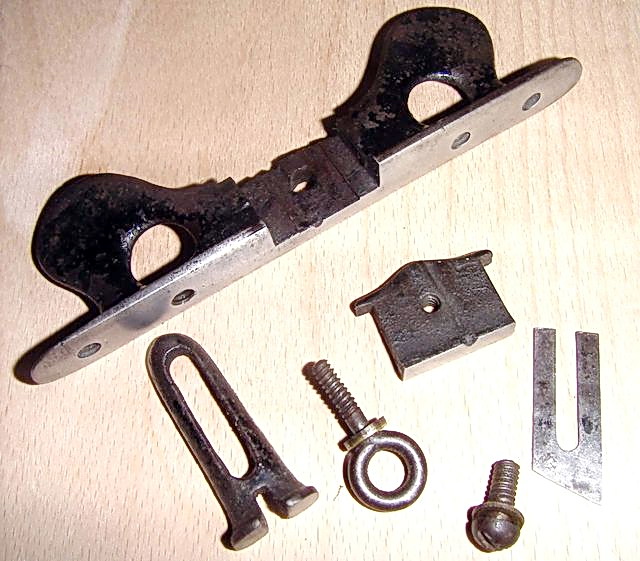

The Lee Valley Cast Scratch Stock is a remake of the Preston's Patent Reeding, Rabbeting and Moulding (Tool No.1393S). Here are photos of the original Preston ...

The Lee Valley version ...

There are a two changes, apart from the cutters. The first is the screw for an eye bolt on the lever cap.

Secondly, the original fence has a straight face - although I have seen a photo where the Preston is supplied with two fences, the other being a curved face. The Lee Valley is only supplied with a curved face ...

When I purchased this scratch stock, it was to create beads for drawer slips ...

The first ones were built with a Lie Nielsen #66 ...

Here is a break down of the Lee Valley (Preston) alongside the #66 for comparison. The LV is significantly smaller. One of the reasons I was interested in purchasing it was for use on curves or small sections.

The LV cutters are shorter and thinner than those supplied by LN. I like the LN for their solid construction. The LV cutters will flex more. What I like especially about the LV cutters is that their arris is so much finer, and this is able to cut a finer, sharper profile. For this reason, I tend to use the LV cutters, even in the LN #66. The downside of the finer arris is that inattention when scraping can cause the sharp edge of the arris to slice into or across the formed bead. Stay focussed!

Here is the cutter in the #66 (and remember this photo for later) ...

In scraping a bead, it is helpful to define the inside edge with a cutting gauge. Alternately, gently draw the cutter along the workpiece progressively scoring the line deeper.

The next step is to remove some of the waste at the outside with a fine chamfer using a block plane (this simply saves some of the effort one would have to go to with the scratch stock) ..

The nice feature of this scratch stock is that it is easy to set up the depth of cut (using the cutter in line with the body). There are indents within the cutter holder to aid in returning the cutter to the same position. The fence may be swapped to either side, which is important when the grain direction changes.

On the other hand, this is not an easy scratch stock to use. It is definitely not a first timer's choice. The reason for this is that the curved fence offers very little registration, and care must be taken to hold the body square to the side of the work piece. The face of the fence is short, and I wonder whether there is much advantage in curving it, and whether a flat face would not be a better alternative. In Part II I make one from scratch, and then examine a different method of setting up the scratch stock.

In use, one can angle the cutter in the LV, which one cannot in the #66. The #66 is designed to scrape in one direction only, where as the LV is more flexible in this area, being capable of cutting on the pull or the push stroke.

Both tools enable the fence to be switched from one side of the cutter to the other, and there is little to choose in this regard. I have added a slot to the LN knob as finger tight is not enough. Consequently both systems require a screwdriver to adjust the fence.

Given the choice of this LV, which is inexpensive at $36 (USD), or a more expensive used Stanley or Record #66 on eBay, which may sell for double this, I would advise that one saves the extra pennies for the #66, especially if you are starting out. I just do not think that the LV is a tool for a beginner. The #66 is just a more solid, easier to use performer. My opinion is very much biased by the curved fence, however, and this may change once I have experimented with it. As it stands, the LV is capable of good work, but with more attention required to do so.

Part II – the square fence and setting up a scratch stock

I built a new fence out of brass angle. Tools were a Dremel and cut off wheel, and a couple of files.

The parts details:

Note that the underside of the fence is curved to mate with the scratch stock bed …

So does the straight fence make a difference? In a word, yes. The extra reference area is immediately apparent, and less effort is required to keep the scratch stock from twisting or turning with the grain. It is much easier to keep the tool moving in a straight line.

I have used the curved fence enough to feel confident using it, and I do achieve reliable results now. Nevertheless I am aware that I push it against the work piece harder than I need to do, and there is more of a learning curve.

Setting up

When inserting the cutter, it is tempting to set the profile flush with the bed. This is logical if one expects to use the bed as a depth stop. It would then look like this …

This does not work – it will cut for a while, however the cutter will quickly clog up with shavings and then stop cutting accurately. Additionally, shavings will become stuck in the gaps alongside the cutter. You will spend your time digging it all out with a pointy thing. I know!

Well, it was logical to me to set it up this way at the start – after all, this is the way it is set up in the Lee Valley catalogue and manual, and it is pictured this way on the original Preston photos. Trust me – it does not work for long.

Examining the set up for a #66 (above), it is evident that the cutter stands out from the body and has space around it. As a result, I set up the cutter in the Lee Valley Scratch Stock in the way that they recommend one does not do (!), which is with the cutting area free from the body …

And this works! And works well. No clogging, and clean cuts.

It is very important that scraping is begun with very light strokes – preferably work with the grain until the arris is cutting in a defined manner. (light strokes control scraping into the grain). I find it easier to pull the tool.

It is possible to make excellent mouldings this way, and both the standard curved fence and the straight fence can produce these results on convex and concave curves …

Some detail …

Summary

When I first started using the Lee Valley (Preston) scratch stock, I found it difficult to control and that the cutter clogged quickly. With practice, the curved fence became controllable, but I think that Lee Valley should supply a straight fence as well. The one I built works as well for curved pieces, and it is much easier for someone starting out to use on straight sections. The cutter benefits from being set up in a non-recommended manner. This, however, means that there is no depth stop. Still, the tool is capable of really excellent work, and in part this is due to the cutters supplied by Lee Valley.

Regards from Perth

Derek

July 2016