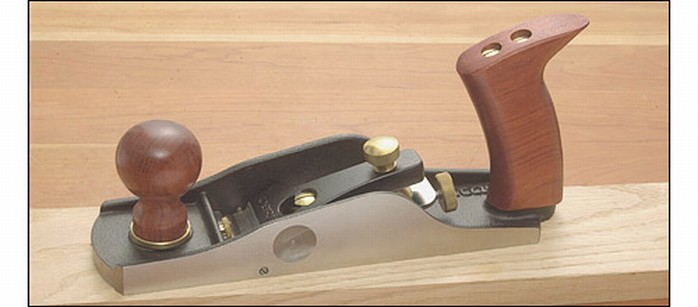

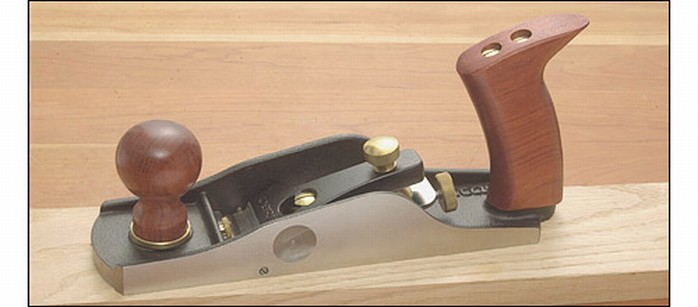

The Veritas Low Angle Smoothing Plane

Introduction

The Veritas Low Angled Smoother (LAS) has been available for a few years now. This, together with the Veritas Low Angled Jack (LAJ), formed the first two – and most recognized – of Veritas’ entry into the production of what now are termed “Bevel Up” planes.

The concept is not new, nor is it unique to Veritas. Lie Nielsen market similar models and, in fact, the inspiration for the planes came from Stanley, who manufactured the #164 (the original name for the LAS) between 1926 until 1943. The #164 did not sell well and so few remain, which is why today these are very highly sought after by collectors.

In recent years, the #164 was re-introduced by Lie Nielsen (as the #164), and then followed by Veritas (the LAS). Both planes are very similar, with just a few distinguishing differences (for a detailed comparison of the Veritas and LN versions, read Alf’s excellent review). The question that must first be asked is, “if this plane was not successful before, why is it being manufactured again”?

The simple answer is that the LAS offers so much more that the Stanley #164 did, not only in construction, but also in scope. Just how we now perceive the way in which the LAS will be used is a world away from the way it was intended when the original #164 was launched.

The #164 is technically a “block plane”.

Patrick Leach, in his fine website, Blood and Gore, recorded, “Stanley, in their marketing propaganda, claimed that "A Block Plane was first made to meet the demand for a Plane which could be easily held in one hand while planing across the grain, particularly the ends of boards, etc. This latter work many Carpenters call 'Blocking in', hence the name 'Block' Plane." This, if it is to be believed, dispels the myth that block planes are so named because they were first used on butcher's blocks”.

My impression is that the market for #164 was the cabinetmaker, and most carpenters would have viewed this plane as a luxury and preferred their Stanley #60 ½. This is not surprising since the planes were then constructed from grey cast iron, which was relatively fragile. These low angle planes were very thin around the mouth, and this had a reputation for chipping. So hardly the type of plane that one might carry from job site to job site.

The

second, and perhaps most pertinent factor as far as understanding why

there was a re-issue of the #164s design, is that there has been a

change in perspective in regard to how the bevel up concept can (and

does) function.

The Promise of the Bevel Up Plane

The original #164 was conceived to be used in the same manner as existing small block planes of the day, that is, as a handplane with a low cutting angle. The plane’s bed is set at 12° and the blade is honed with a bevel of 25°. This creates a combined cutting angle of 37°. By contrast, a standard bevel down Stanley #4 smoother (which is the same size plane) has a frog at 45 degrees, which creates a cutting angle of 45° (since the bevel angle is not a factor in this calculation).

The promise of a bevel up plane is realized when it is used with blades that offer different bevel angles. For example, in addition to the low angle (37°), one might hone the bevel at 33° (cutting angle of 45°, or Standard pitch), 38° (cutting angle of 50°, or York pitch) or 50° (cutting angle of 62°, or Half pitch).

As a rule of thumb, a low cutting angle is best on end grain, while a high cutting angle is best on reversing grain where tearout is a serious risk.

In other words, the promise of a bevel up plane is the wide range of uses to which it may be put. With just a change of blade, it can be transformed from a plane that cuts end grain on a shooting board, to a plane cutting face grain in soft wood, and to a smoother dealing with gnarly hardwoods.

The Promise of the Veritas LA Smoother

The bevel up design creates a low centre of gravity, and this aids control.

A thick blade (1/8”) to aid stability and reduce the possibility of chatter. This is made of A2 tool steel hardened to Rc60-62.

A wide range of effective cutting angles, especially very high angles. The LAS comes standard with a 25° bevel, which yields an effective cutting angle of 37°.

With its adjustable mouth it has the capability to be set up for the finest of shavings.

Blade stability is further increased through

Alignment by set screws on each side of the blade, and

A long and wide bed that supports the blade down to the mouth.

A substantial front knob and rear tote. The rear tote has double bolts for additional rigidity, compared to traditional bench planes such as the Stanley, which use only one bolt.

Precise blade adjustment (through a Norris-style adjuster). Blade adjustment is in two planes – blade projection and lateral adjustment.

Set

screw

Finally, the LAS is constructed of Ductile iron which, unlike grey cast iron, is nearly indestructible.

The Performance

I purchased this LAS approximately 18 months ago and the following is a summary of my experience and observations using it over this time.

a. The Objective Results

The LAS has been used on a wide variety of woods, ranging from soft pine through to the knurliest of Australian hardwoods, such as Jarrah, Karri and Blackbutt.

While straight grained and undemanding soft woods can be planed without much fear with a low angle blade, gnarly hardwoods are best treated with respect and planed with a 62° cutting angle.

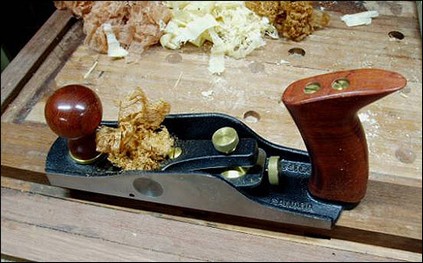

LAS

creating shavings on Camphor at approximately 0.0000”

The above picture reveals the LAS’ capability on camphor, a softwood with frequent sections of reversing grain. This was consistently achieved without any indication of tearout. To emphasize this point, I was not able to plane this successfully with either of my favourite Stanley planes, a Bedrock #604 (with Lie Nielsen blade and chipbreaker) and a Type 12 #4 ½ (with Clifton blade and chipbreaker). The gap between the LAS and the Stanley planes was further widened when the LAS was able to complete a tearout-free performance against the grain.

LAS

on Karri

One

of the toughest woods to plane, owing to a combination of hardness

and constant short reversing grain, is Karri. Again the LAS was

capable of a near-flawless finish in high angle mode. The Stanley

planes again left significant tearout.

In summary, the

performance of the LAS in high angle mode was simply in a different

class to the Stanley planes, which were set up in standard mod.

b.

The Subjective Performance

I

have previously described the differences of a bevel up plane verses

a bevel down plane in use (see Veritas

BU Smoother

review). The LAS performs identically to the BUS. I have paraphrased

and updated the earlier comments below.

Setting and fine-tuning the blade is a doddle with the LAS.

With the LAS you slide the adjustable mouth forward (to guard against the blade edge striking a metal surface), place the blade on the plane’s bed between the set screws, replace the lever cap, return the sliding mouth to its preset position, then fine-tune the blade for square and projection.

With the Stanley, you must first re-position the chipbreaker on the blade as close to the edge as you can, place the blade on the plane’s frog, carefully attempting to centre the lateral adjustment level, replace the lever cap, then fine-tune the blade.

While these steps appear very similar, they are so much fiddlier with the Stanley. For example, the setscrews on the LAS permit the blade to be placed in the same position as before. The adjustable mouth has a stop that returns it to the same projection as before. It is possible to get very close to the previous depth of cut by extending the blade to the edge of the mouth.

With the Stanley, many things may go wrong. If the chipbreaker is set a fraction to far forward or too far back, it will impact on the depth of cut setting. If the chipbreaker is not cantered on the screw in the middle of the frog, the lateral adjustment lever will be skewed more to one side than another, making it more difficult to adjust to centre. Setting the mouth size on a Stanley bench plane requires removal of the frog (since the adjustment screws are positioned under the blade), followed with a trial-and-error approach to get the desired setting. Bed Rocks are partly desired for their ability to by-pass this last stage (as they have external adjustment screws).

Comparisons with the Veritas Bevel Up Smoother

LAS

(left) and BUS (right)

A more detailed discussion of the BUS verses the LAS was reported in the review cited above. The question that is asked is whether the newer BUS is the better purchase, and whether the older LAS is still competitive.

The short answer is that these are two different planes, each with strengths and weaknesses.

The LAS is a smaller and lighter plane, more easily approximated by a Stanley #4. The BUS is a larger, heavier plane, more easily approximated by the Stanley #4 ½. The LAS offers more direct “feel”, while the BUS has heft and this translates into added momentum and “control”.

Overall, the performance of these two planes is similar, if not potentially identical, but the BUS is able to achieve it with greater ease (that momentum thing).

The BUS is a dedicated smoother. It has no other use. The LAS has a wider range of uses. The BUS cannot be used on its side since it is not flat. The LAS is perfect for using on a shooting board, and really excels in this mode.

The

LAS on a shooting board

In short, the BUS excels as the ultimate smoother. The LAS is the choice for those that seek to use a plane that excels on the shooting board as well.

A

postscript on this last point: I would not dedicate a low angle blade

to the BUS since it will not be used in that mode. The LAS, on the

other hand, would benefit from 2 or 3 blades to cover a wide range of

bevel angles.

The

Tote

The LAS’ tote has come in for criticism from some users. In comparison to the Stanley tote, it has a vertical orientation.

LAS

vs. Stanley totes

It should be pointed out that Veritas have since introduced a new tote, which is seen on the BUS (above), and this has added curvature at the centre.

Some experience the LAS tote as comfortable, while others do not. I believe that this is not simply a function of the size of one’s hand (which, obviously, must also play a part), but largely due to the height of one’s workbench. The vertical grip is better suited to more modern higher benches where the push is forwards and horizontal. The angled grip of the Stanley is better suited to the traditional lower benches where one pushes downwards.

Conclusions

While I may be criticised for comparing the LAS in high angle mode with Stanley planes in standard mode, since these are not equal mediums, this situation serves to illustrate the very essence of the LAS. The LAS is capable of being used in a wide range of blade angle modes, where as the Stanley plane has just one mode.

The LAS is capable of first class performance, whether with a low angle blade on a shooting board, or with a high angle blade on some of the most testing wood available.

This is an easy plane to set up and use, one that will quickly enable a novice to create shavings that rival those of an experienced user.

The LAS is an obvious recommendation for the short list of all those considering a new smoothing plane.

Derek

Cohen

Perth, Australia

March, 2006