The Veritas Combination Plane

More on dados or housing joints

A

question came up about the width of a dado off a dado plane … that

the width of the dado cannot be calculated from the blade, per se,

since the nicker is an additive factor.

Positioning the

nickers is at the heart of setting up a dado plane, be it of the

combination plane style, where there are individual nickers, and

placed at either side of the plane body. A combination plane extends

the width of the body using two skates. There is a second type of

nicker system, which is a single nicker divided into two cutting

sides. This is the version used by many vintage woodies and, more

recently, HNT Gordon.

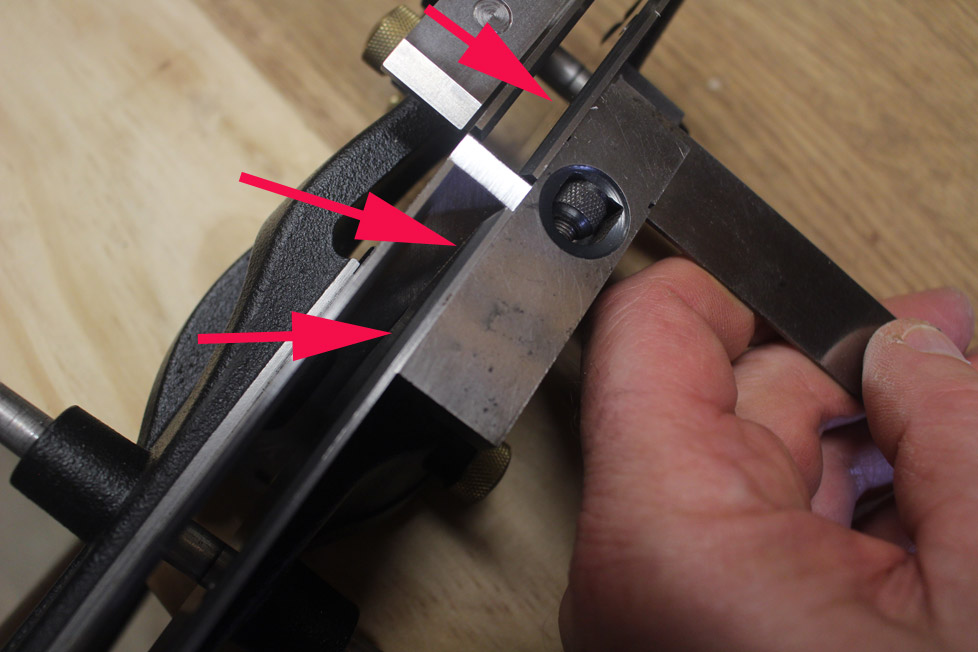

Close

up of the nicker …

With

the Veritas, there is a nicker on the outside of each skate

...

This

is adjustable, using a set screw, which pushes the nicker/blade away

from the body.

My preference (which runs against the

recommendation of Veritas) is to remove the set screws (because they

fall out and get lost otherwise) and set the nicker for minimal (more

on this in a moment) projection from the skates. As mentioned before,

I rounded the tips of the nickers (they came pointed). There were two

reasons for this. Firstly, the original tips of my pre-production

plane were fragile and broke off. I hardened them. Secondly, the

rounded edge seems to me to slice more easily than a pointy tip, and

the plane cane be drawn back of the work piece as well as pushed

through it. In other words, it is less directional.

The

depth of cut is not really a number. Numbers are starting points. Say

1/16". We really want the nicker to be set a smidgeon more than

the depth of cut, as it needs to slice the cross grain ahead of

the blade. Too deep and the nickers will just make the plane harder

to push.

Now

warren made an important point at the start of this thread when he

wrote that, because the nickers must lie outside the side of the

blade, they cannot leave a dado the width of the blade. I agree with

this, and it becomes the main topic here.

If using power tool

methods, it is possible to prepare boards (to fit) and the dados in

an interchangeable order, since they can be made to the same width.

For example, a 1/2" power router bit creates a 1/2" dado,

and one can thickness 1/2" thick boards quite separately. On the

other hand, if using hand tools, it is relevant to create the dado

first and the board thickness second - based on the width of the

dado.

The question is "how close to 1/2" can

we create a dado?". In other words, assuming a 1/2" wide

dado blade (straight or skewed), what is the minimal amount of dado

projection we can get away with before the side walls begin to

spelch?

So I set up a simple examination (this took far less

time than the write up!). Veritas and HNT Gordon planes and a

small piece of Radiata Pine scrap ...

The

Veritas blade is exactly 1/2" (as one might expect) ..

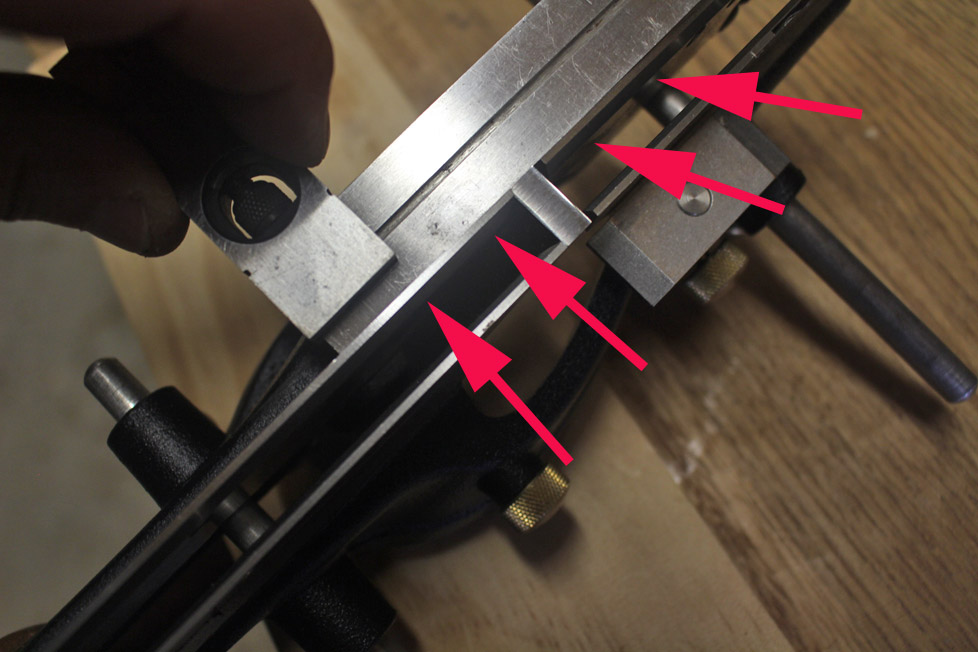

Now

I have stated before that I set up the nickers flush with the sides

of the skate (and then adjust the skates outside the blade). This is

not quite accurate. Indeed I set them up this way ...

Why

I say that this is not quite accurate is that my nickers have been

used with the set screw, and this has deformed them very, very

slightly. So now, when I try and set them flat against the side of

the skate, they do not sit flush, and project very, very slightly. I

cannot measure the amount of projection, only feel it with a finger

tip. This has a bearing on the set up and the results. More in a

short while.

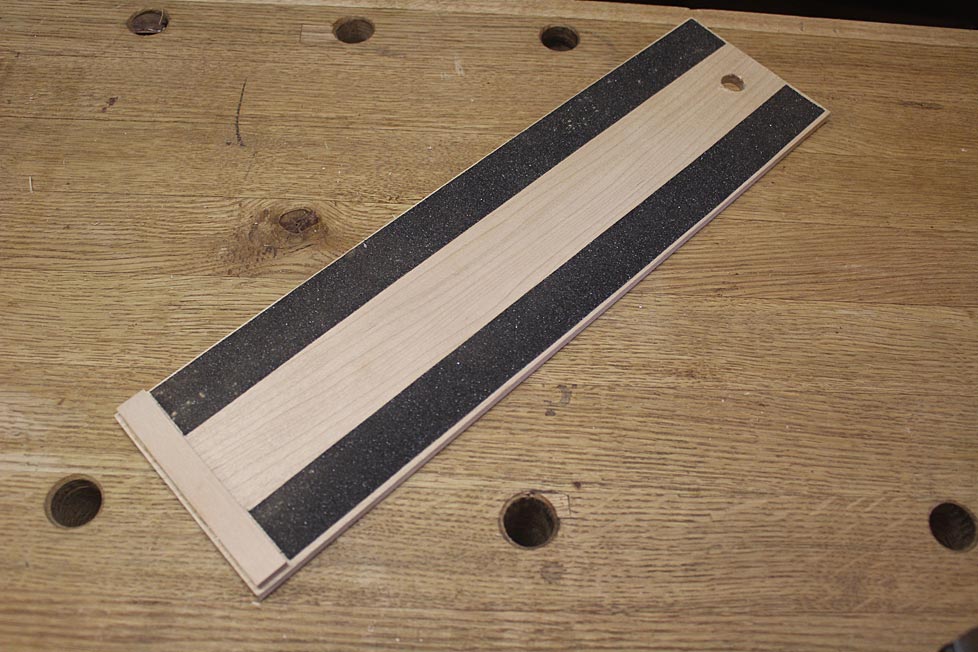

Here is a tool needed for planing dados - a

straight edge. Traditionally, one would simply nail a wooden fence to

the work piece. The nail holes would be either filled or ignored. The

Veritas requires the fence to be a 1/4" high. So I have a

straight edge with non-slip and a square reference at one edge

...

If

the work piece is held firmly, it becomes a simple matter to clamp

down the straight edge ...

I

then pull the plane back against the fence, but very lightly. All I

want is a positioning of the outside nicker ...

Nickers

are not always the cleanest cutters - not sharp enough - for leaving

a pristine side wall. And so I prefer to knife them in ...

Now

go ahead and plane the dado, beginning at the far end. The depth stop

will keep it level (note that I have not relieved the end of the dado

here, as I generally would to prevent spelching. This example is

about the nicker, not the finish at the end of the dado. I am not

even using the depth stop).

How

wide is this?

That

is 0.55mm/0.02" wider than the blade. mmmm .... not that great a

result as far as I am concerned. I am sure it is possible to do

better.

The HNT Gordon dado plane is my reference here. It is

set up in a similar way, but stock standard. The blade was previously

measured also as exactly 1/2" (12.71mm on this occasion). It has

a skewed blade, but that only affect the cleanness of cut (the skewed

blade leaves a cleaner finish). The nickers protrude from the body of

the plane, but again I can only feel this with fingertips as it is

not obvious.

A clean slate ...

Planed

...

Measured

...

That

is a better result than the Veritas. So, let's try the Veritas again,

with the skates set up a tad closer together ...

That

is a tighter fit for a 1/2" thick board, and visually it looks

good in that there is no spelching. As I look at the photo now, I can

see compression on the right sidewall. It is not present on the left

sidewall. Is that from knifing the line, or from the nicker?

In

conclusion, as one moves the nicker closer to the blade, the leeway

for error is lowered. One question is "Is it worth it?". I

guess the answer is that one needs to recognise that hand tool work

is best done in a specific order. Power tool thinking needs to be set

aside here. It is evident that one can get pretty damn close to the

width of the blade - the amounts exceeded here are unlikely to be

registered visually - and that the amount of leeway can be pretty

damn small.

Regards from Perth

Derek

March 2019