Return

the Sharpening Techniques

The

Bench Sander Blade Grinder MK II

The

following article is a composite of posts written on the Ubeaut

woodwork forum from April

2005.

I have

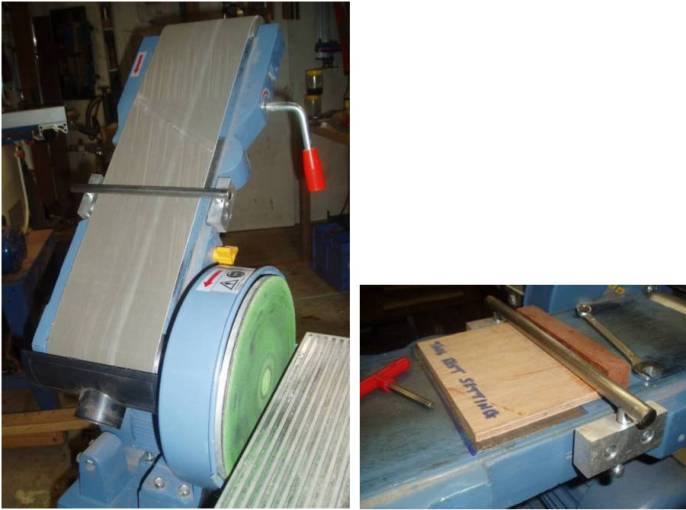

replaced my Belt Sander Grinder with Mark II. This not only involves

a new jig, but also a new machine.

The original machine

developed electrical problems (in the on-off switch) and, after one

unsuccessful repair, I accepted Carba-tecs offer to return it (at

full refund) and upgrade the machine (my cost). Its replacement is

the Carba-tec SB-609,

a 6”x9” machine. Compared to its predecessor, it is

bigger and more powerful. Note that this is not necessary for the

purposes of grinding/sharpening blades, as the original machine was

satisfactorily specified in spite of being 1/3 hp and 4” wide.

Carba-tec

described the SB-609 as follows: New model

features graphite slip pad and dust extraction outlet. Powerful 3/4

hp motor will not stall under pressure. Disc table tilts to 45

degrees. Belt platen swivels for horizontal or vertical sanding.

Quick-release lever makes for fast belt changing. Stand and mitre

guide included.

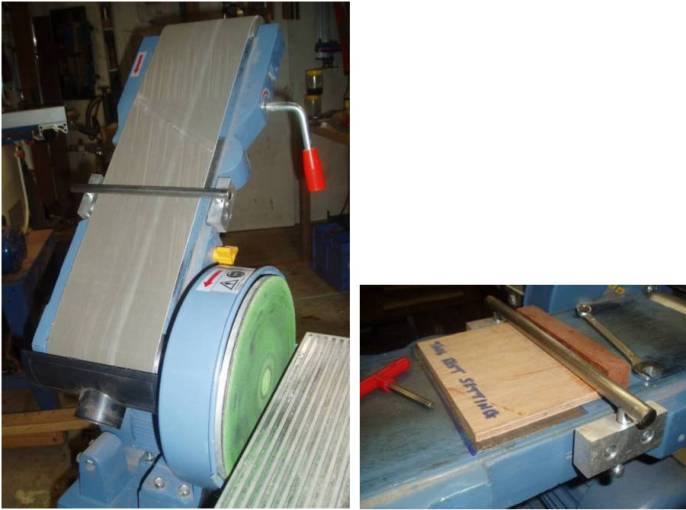

I needed to fit a jig

to the new machine and, although I could modify the old one to fit, I

thought that I'd make a new one – one that included all the

features I had previously described in the earlier article.

The

other area I was interested in sharing was my efforts in machining

metal, in this case aluminium, with the few related metal working

tools I own. If I can do it, then others can too!

Below is a

picture of my Poor Man’s Metal Machining setup: drill press,

2-dimension vise, drill bits, cheap set of taps and dyes, squares,

scribe, digital caliper.

It

begins here …

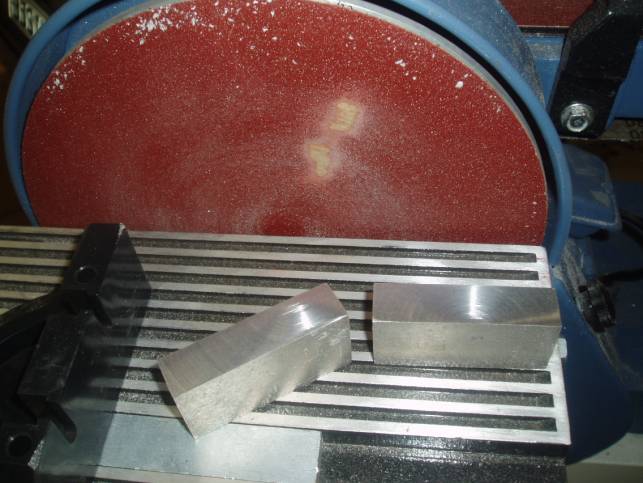

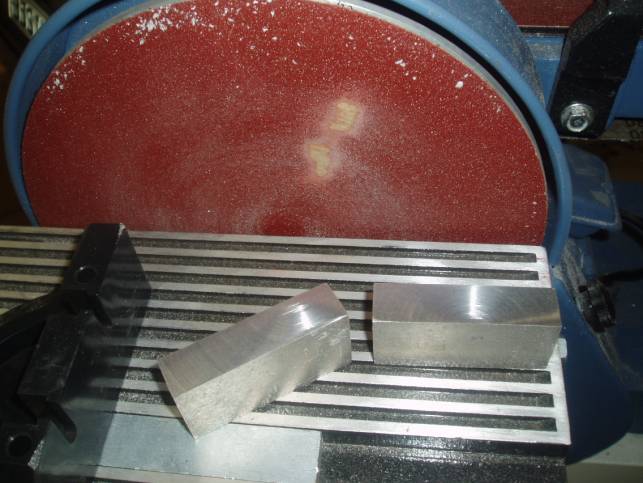

The first step

was to cut up a few pieces of aluminium. I did this on a Mitre Saw

(cheap GMC) …

… then

ground them square on the belt sander …

The

plan for the jig was to modify the design by adding height

adjustability to the toolrest, a feature which many contributors have

believed important. I agree – height adjustability is not so

much a factor for setting the blade as it is for setting the tool

rest perfectly parallel to the table top. My earlier suggestion had

been to drill completely through the tool rest sideblocks, and to add

a height adjustment screw from underneath the block.

Drilling

the blocks accurately is made possible with a drill press and vise.

Make sure than you lubricate the drill bit otherwise it will overheat

and snap (don’t ask me how I know!). Below is a picture of the

underside of the drilled block, revealing that I got it right!

Height

adjustment screw: Drill a pilot hole all the way through the block.

Mine was 28 mm thick. Then drill from the underside 8 mm deep for a

thread you will later tap for an allen head bolt. From the other

(top) side drill a 20 mm deep hole for the toolrest legs (mine are

9.64 mm in diameter, so I used a 10 mm drill bit).

Tap the

height adjustment holes for the allen head bolt.

In

the next picture (below) you can see these holes more clearly.

Finally,

drill the two holes that will fix the new toolrest block to the side

of the belt sander, and then drill to recess the bolts (also allen

head bolts). This completes the toolrest blocks. See picture below.

Here is

the pic of the final set up.

Note

that the belt sander table top was stripped of the graphite slip that

comes as standard equipment. This tends to be easily depressed when

pressure is placed in one spot. The underlying cast iron top was flat

and smooth. Nevertheless, to avoid any later problems with wear, I

contact glued a steel plate to the table. This was cut from an old

hand saw blade (cut with angle grinder, smoothed with files). (Edit:

this later proved unnecessary and was removed).

The

blocks were screwed onto the sides of the sander by drilling and

tapping holes. The set up process is the same as previously described

(in the first article). Care was taken to make sure that the toolrest

was square to the table top.

Steel washers were used as

spacers to center the jig.

The height of the tool rest was

set using a piece of 6mm MDF (reliable flat measurement) under it.

The height adjustment screws were locked in place with additional

nuts.

Instructions

for use

See the article on the MkI.

The

Honing Plate

This has also undergone a change. Where the MkI was

constructed out of two sanding disks epoxied face-to-face, now we

have chamois leather stretcher over and contact glued (use 3M) to the

face of the disk.

Start up the motor and cover the plate with

Veritas green rouge. Then freehand the bevel against this.

Place the blade down heel-first, and then rotate it until it is flat

on the plate. Just remember to hone with the turn. It only requires a

couple of seconds.

Regards

from Perth

Derek

April

2005