Back to Powered Tools and Machinery

Building a MFT: Part Two - making a rail hinge

In the

first segment of the MFT build, the aim was to construct a bench top

that would accept the Festool accessories for work holding. The MFT

would serve for routing, sanding, carving, and as an outfeed for a

jointer, slider and router table.

The 20mm holes were routed

using a CNC-made template.

It

needs to be understood that the reason for making the MFT was partly

due the cost of purchasing one in Australia being excessively

expensive (the Festool MFT sells for $1595), particularly so when I

am not sure how much use it will get.

A large part of this

cost lies in the rail hinge and rail fence, since a typical use of a

MFT is for sawing ...

The

stability and ease of adjustment of Festool rail hinge has come in

for some criticism ...

...

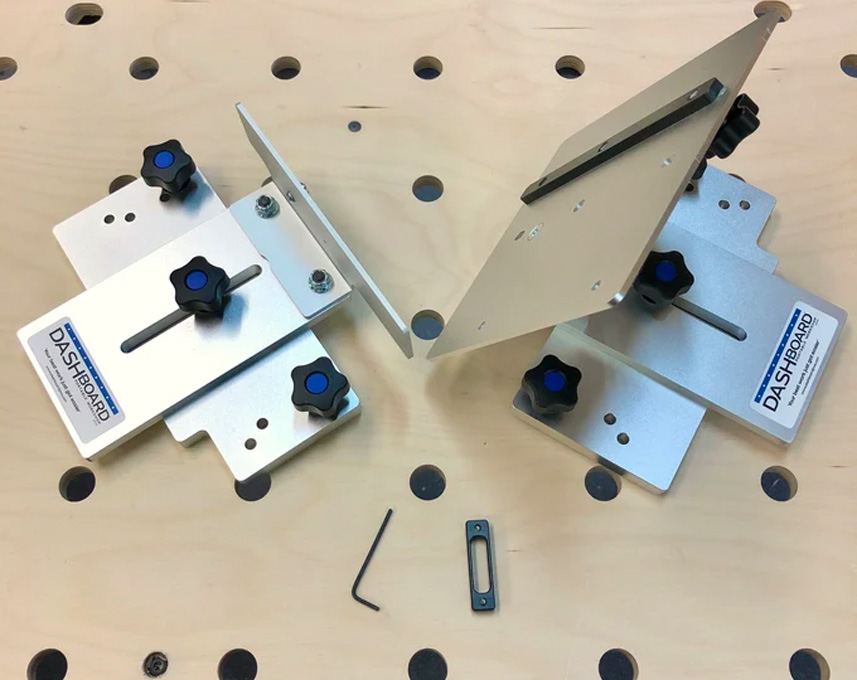

which has lead to aftermarket versions becoming available, such as

this Dashboard hinge ...

This

looks a beautiful piece of equipment, camera-level precise ... but it

would cost around $700 landed in Oz.

So I decided to build my

own. Two considerations - design and materials. The design is a mix

of ideas, some taken from other builds on the Internet, Peter

Millard's hinge design ..

.. and a few of my own.

Fabricating in metal was not feasible as I do not have the tools to

work it. Using ply wood, MDF and even hardwood was rejected as these

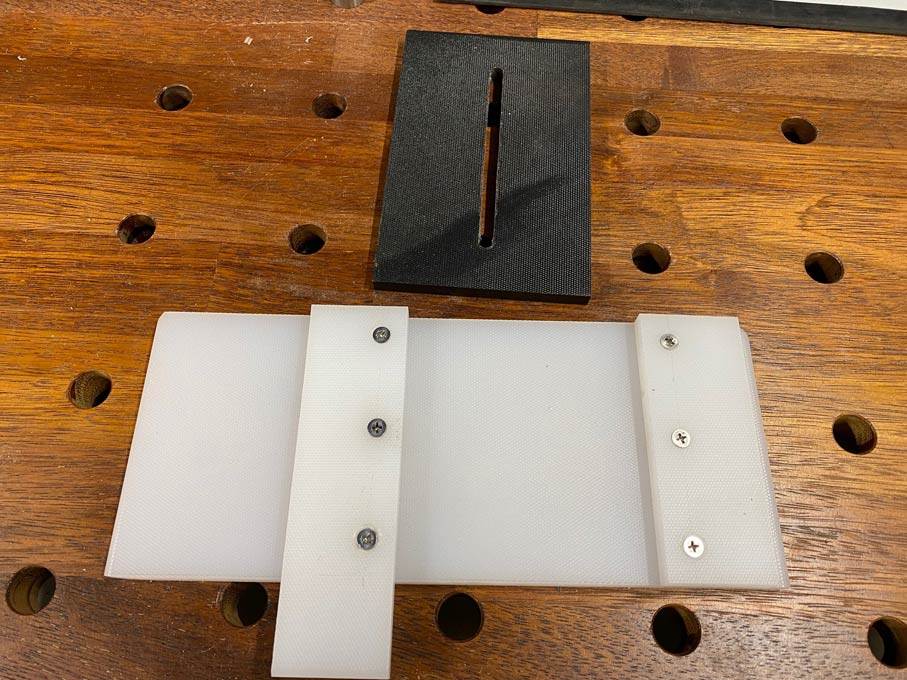

are not durable enough. In the end I settled on nylon cutting boards

- cheap and very hard wearing.

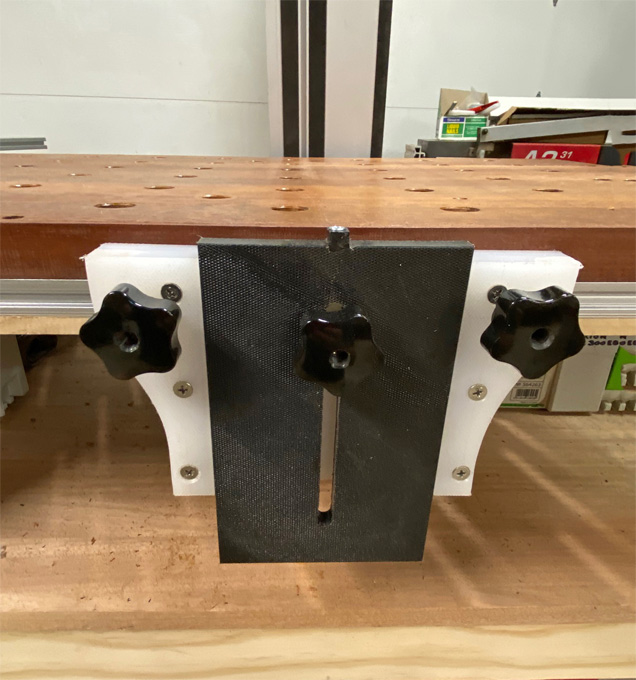

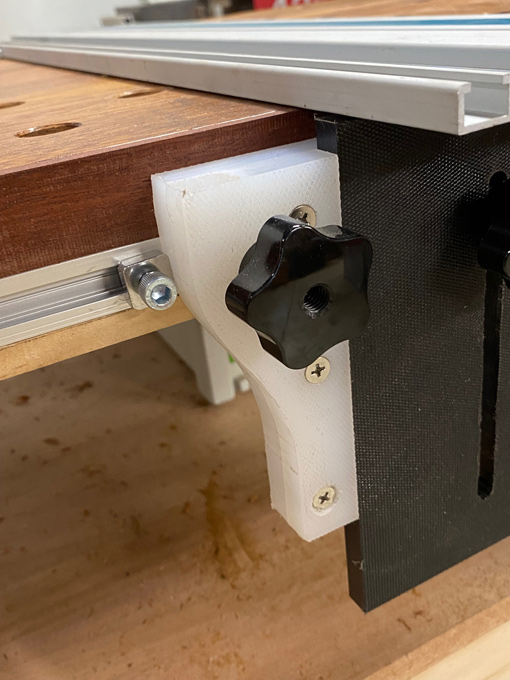

The

nylon cannot be glued, and so all bolt holes were tapped for threads,

and screwed together ...

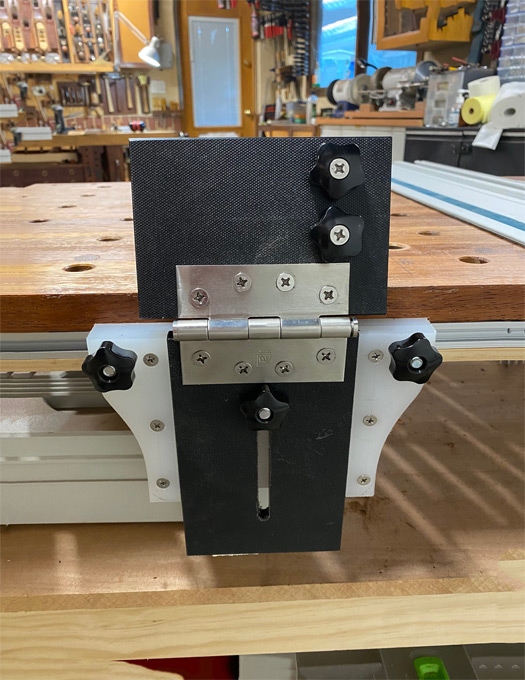

The

dimension across the top is 8" and the height is 5 1/2".

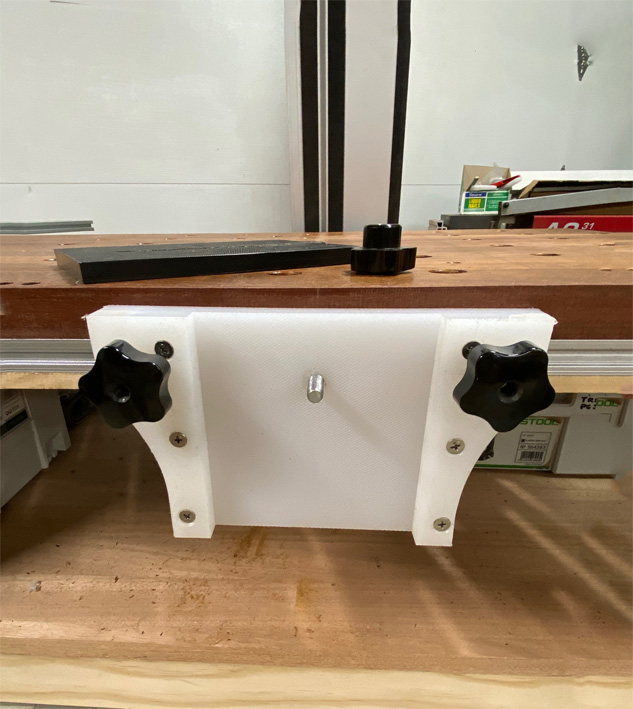

This

holder is used for both the hinge side (where the rail is connected)

and the pin side (where the rail is squared to the table) ...

Two

key factors are present: each part is built with care for precision -

errors are additive and will affect accuracy. Part of this is that

the hinge must not have any play.

The

rail hinge is set at a height below the bench top when not in

use.

The two knobs (above right) tighten the connector to the

rail ...

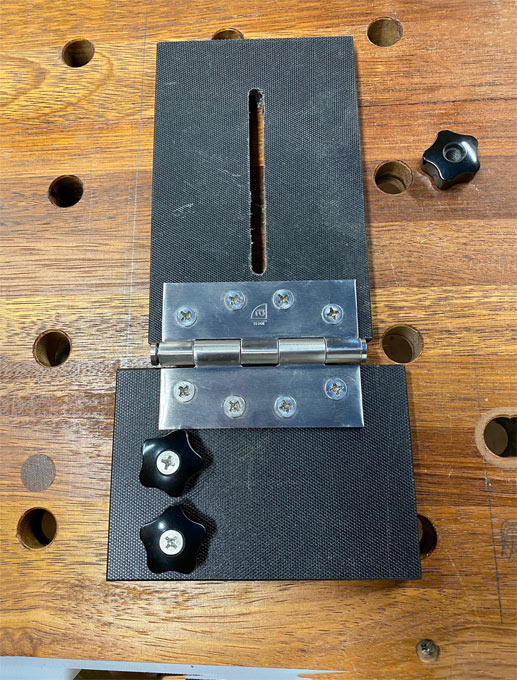

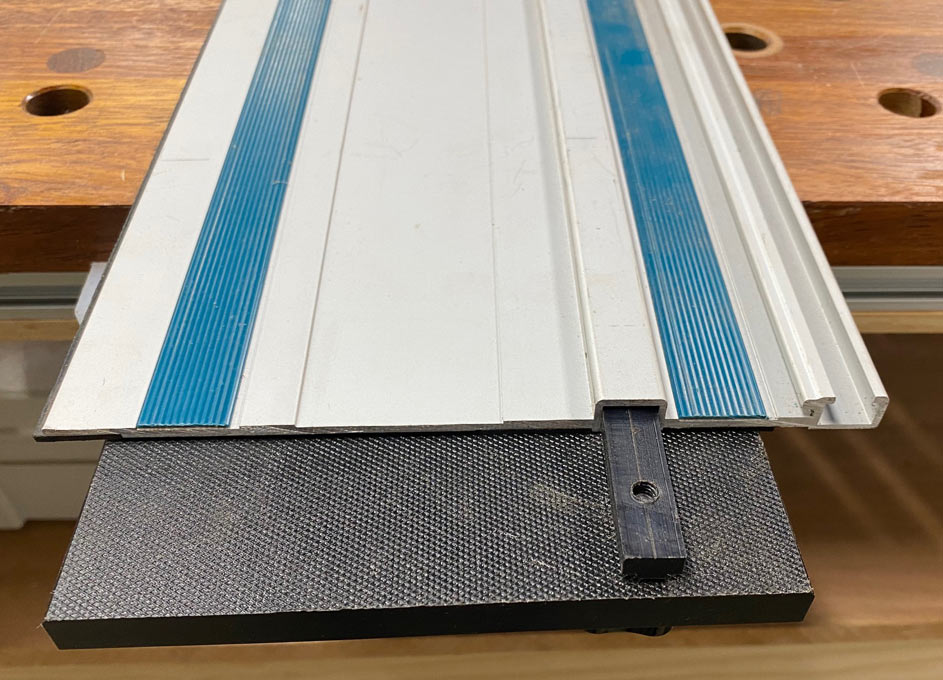

The

rail connector has rebates to fit the rail ...

The

pin in the pin holder is square and sized for a tight slip fit ...

EDIT:

since building, the pin has been moved over to the left side of the

holder. This is to increase/maximise the support the rail receives.

All

together - the rail swings over ....

...

and rests on the pin ...

The

rail is able to be lifted up out of the way in readiness to position

a board ..

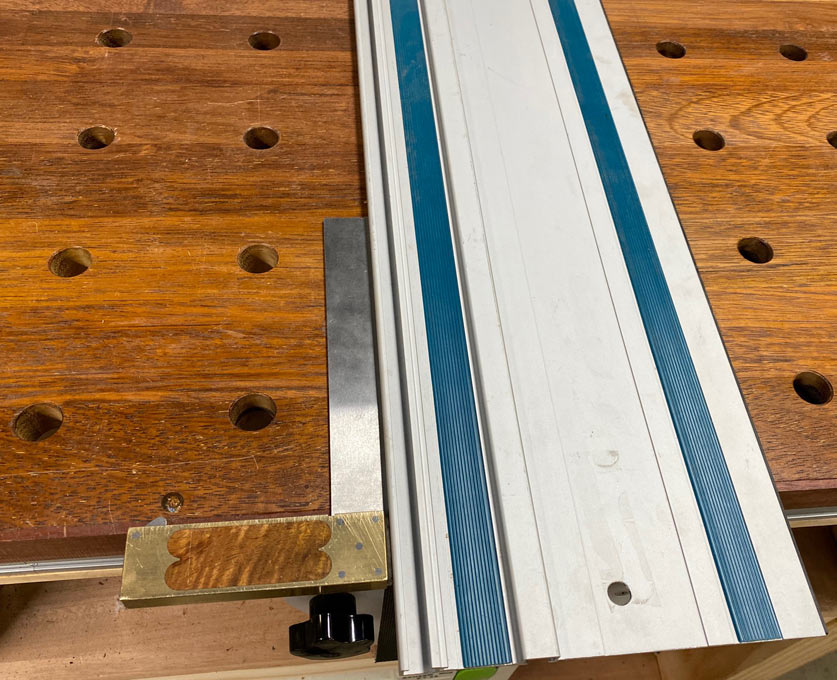

All

feels rock solid.

Checks for square against a rear fence ...

...

and against the front of the bench (the ends are exactly parallel and

all the holes are square) ...

Lastly,

a stop is added to both hinge and pin holders, to allow exact

re-positioning ...

All

the best for the festive season.

Regards from Perth

Derek