This is okay for moderate size work pieces, but larger boards, such as the recent dining table build, requires that the machine be pulled out into the workshop for clearance. This is not so easy since its mobility kit consists of two fixed rear wheels and a wheeled bar for the front.

I decided to fit the mobile base from Timbercon, their Sherwood Heavy Duty model, as this had larger, wider wheels and a sturdy steel frame. It can also handle 680Kg, which is twice that of the A3-31. But what I particularly liked about this mobile base was the four swivelling wheels set at the two ends, which placed them away from the front. This promised good movement and less obstructions. https://www.timbecon.com.au/products...e-machine-base

The problem was now to get the base under the A3-31! Don't do this on your own, folks! Of course I did

This machine weighs in at 290Kg and I do not have any equipment for lifting heavy objects. I discovered that a crowbar works well, pivot point down, and can gain added height with a wooden shim added underneath.

First step was to lift the rear up off the wheels using wooden wedges and the crowbar. This is the key to the whole endeavour. Adding blocks underneath, away from the perimeter (where the base will be) makes all relatively straightforward as we move along ...

This included the front, so the legs could be removed ...

The rear wheels could be unbolted at one end, and then the axel could be slid out ...

Now assemble and size the rear section of the base (the front section will be the same length, so that may be assembled at the same time) ...

Note that the front dimensions (width) of the A3-31 is shorter than the rear, hence the rear is completed first.

This is the fit at the rear ...

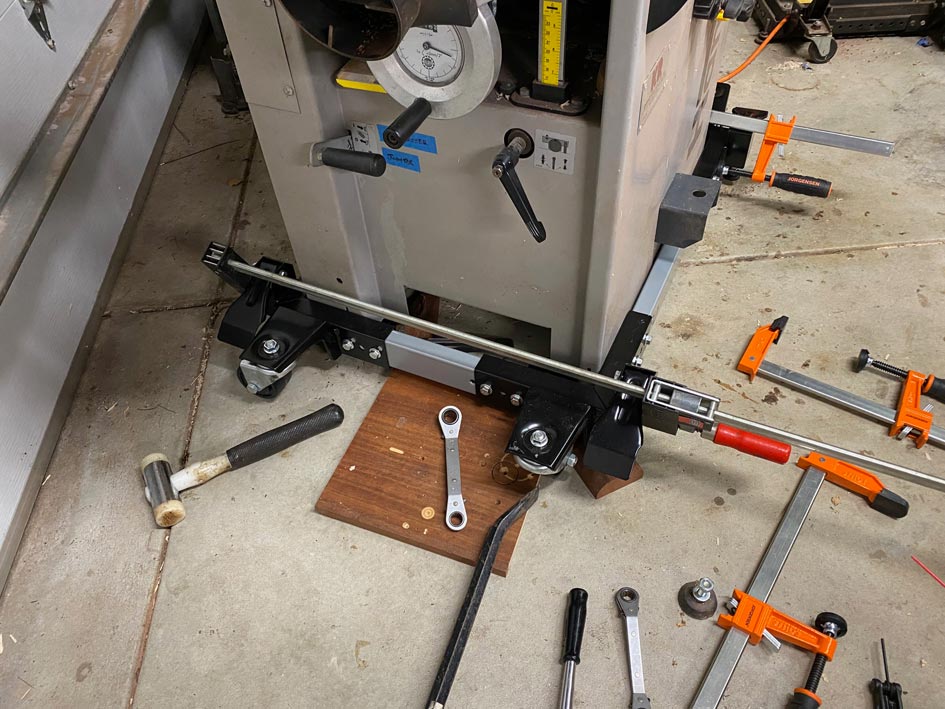

Throughout I used clamps to hold the base against the machine, and then to pull all together ...

Once the rear is in position, slide in the front-and-side sections together. The bolts all are tightened from the outside, so no concerns for wrenches on the inside.

Here are some photos of the fit ..

1. Front

2. Left side clearance at front

3. Right side clearance at front

One all done, it is easy to set the stationary stops (they just screw out to the desired height). You can adjust the stationary height to be perfectly level this way.

In summary, this mobile base fits like a glove. It would have been an easier process had I not had to problem solve this method at the start (where I was hoping to use a hand trolley to lift one side - oh yeah! )

Regards from Perth

Derek