Back

to Powered Tools and Machinery

No

mitre gauge track!

A router

table is a wonderful resource. However, a good router table does not

need to be complex. In fact, I much prefer the KIS principle. My

first router table was simply a piece of MDF with a hole for the bit.

The fence was a 2x4 clamped alongside. It did good work. While this

latest router table has many bells and whistles, it is still

relatively simple compared to many.

This is my solution for a

mitre track ...

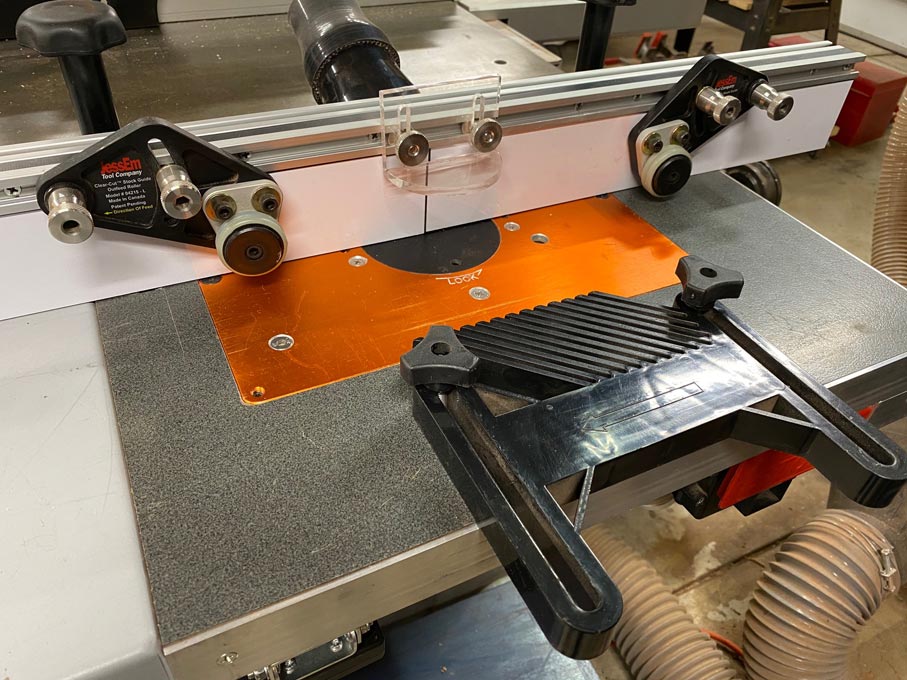

There are two reasons to have a mitre track.

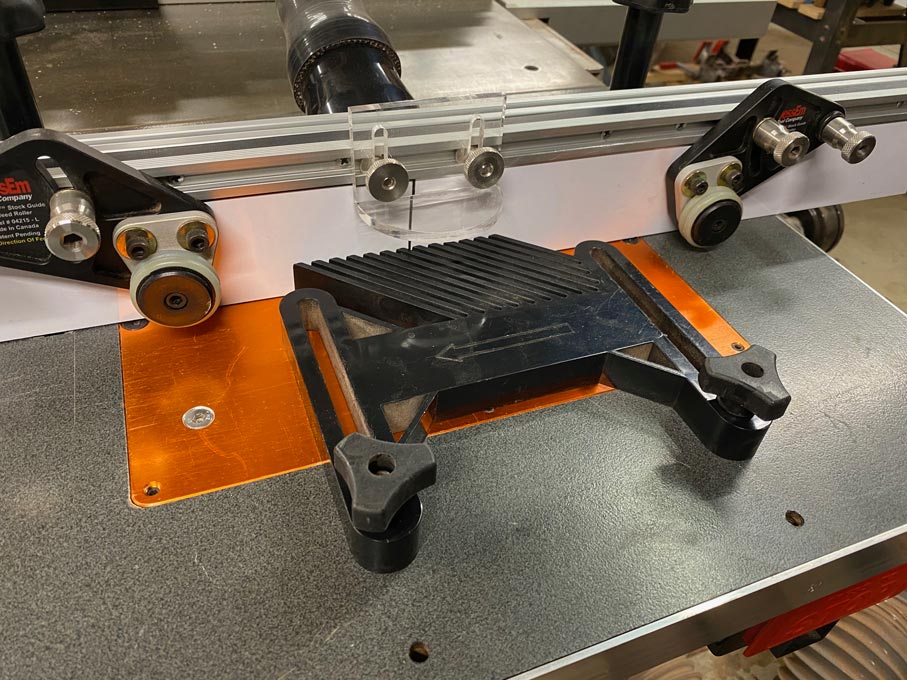

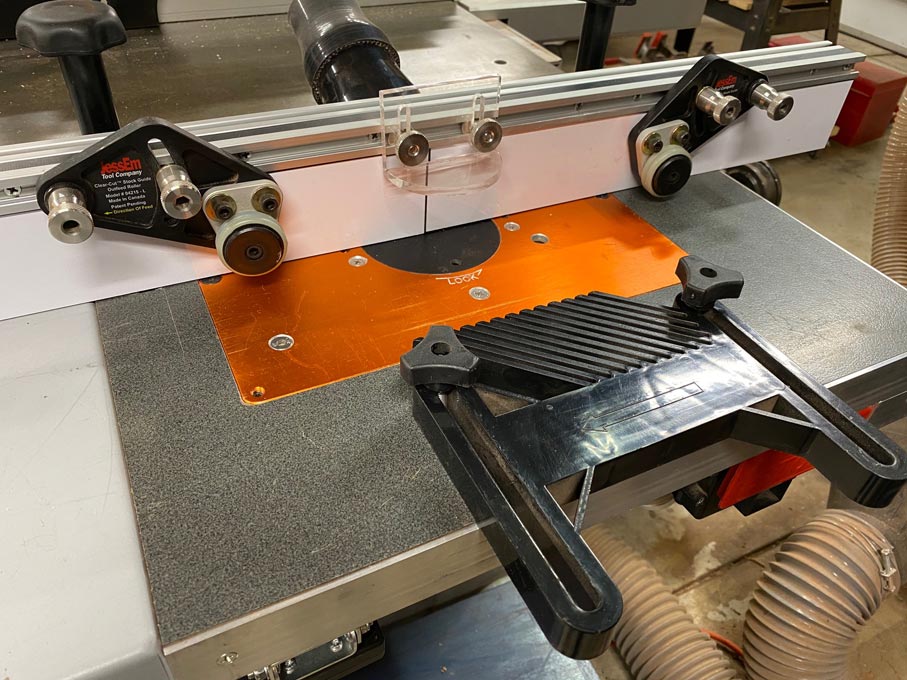

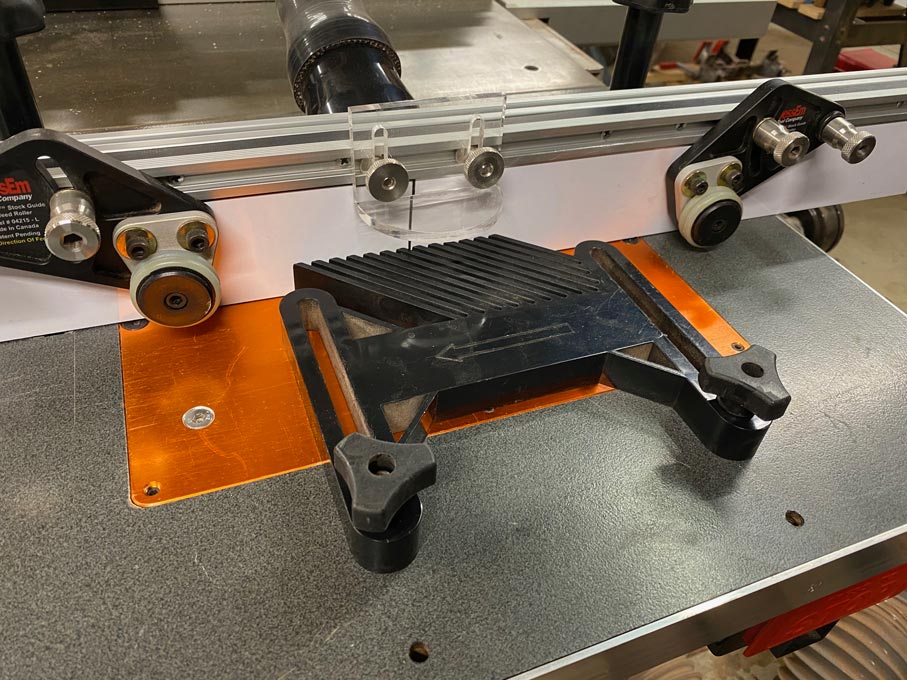

The first is to attach a feather board. As I mentioned earlier, the

JessEm guides do the task of holding the workpiece both down and

against the fence. If the JessEm is not sufficient, I can still

attach a feather board.

I was using a feather board on the

table saw today to size drawer backs ...

The

feather board can do double-duty at the router table. I drilled and

tapped four bolt holes in line with the centre of the table ...

The

feather board can slide back-and-forth when bolted this way. It can

reach to the fence ...

The

forwards holes are where a mitre track would go. This is as far back

as it would extend if in a mitre track ...

However,

the second set of holes allow for a wider range ...

The

second reason for a mitre track is to use a mitre gauge to either

rout out tenon cheeks, or joints such as cope-and-stick frames or box

joints. There are alternate solutions for these.

The main

issue I have with the mitre gauge method is that it requires that the

fence be parallel to the mitre track. Fences are rarely so in my

experience. The closest I came to this was when I had a router table

in a previous table saw, and it shared the table saw fence (which

tracked parallel to the blade). This is not the case now. The fence

rides unequally in tracks, and one side is moved to fine adjust the

setting. In short, a mitre track is useless.

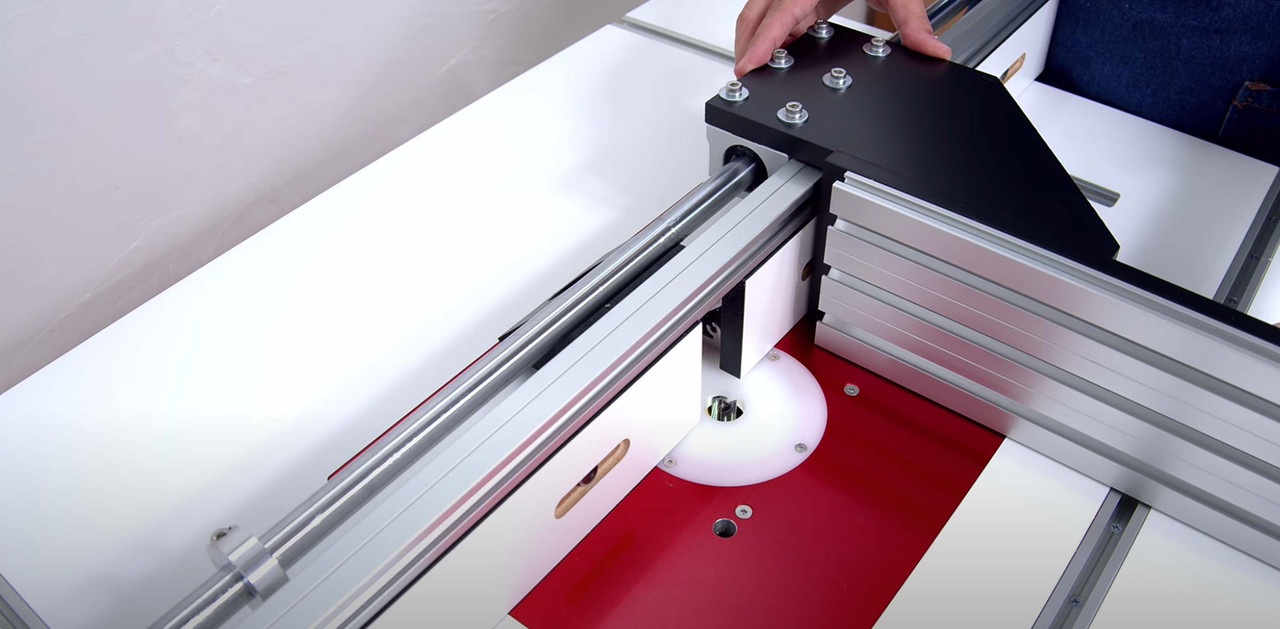

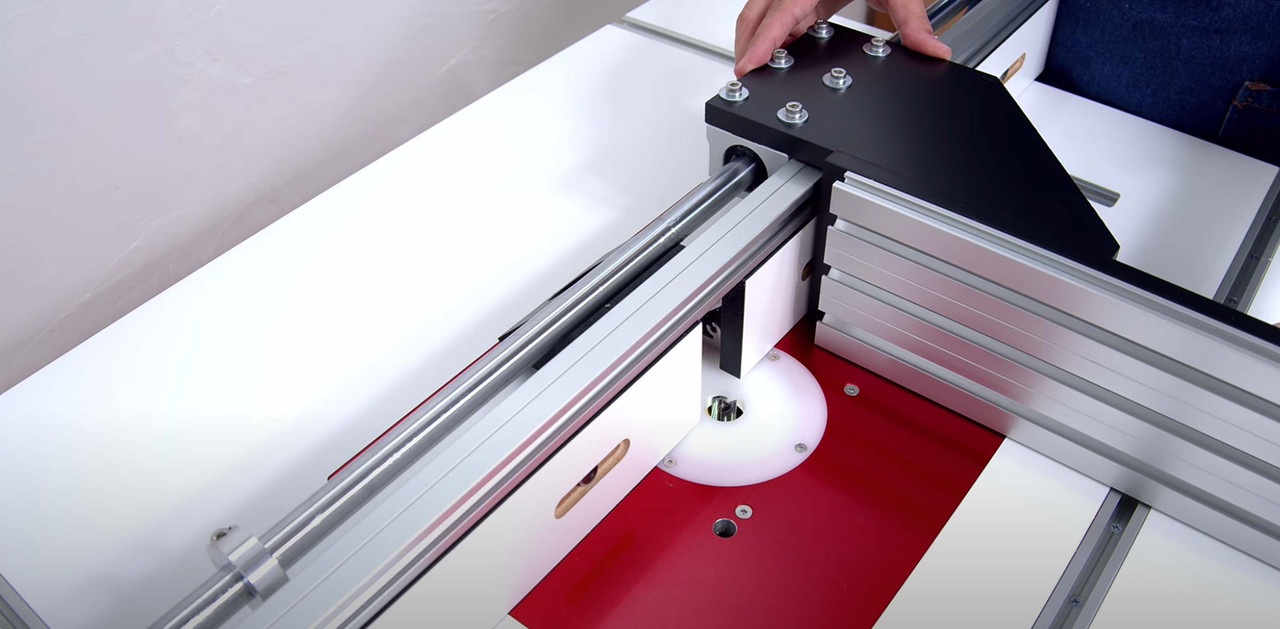

To make a tenon

cheek, or cope the end of a stretcher for a cope-and-stick joint,

simply use a backing board against the fence ...

This

will not make box joints. In reality, for myself, it is unlikely that

I would ever make box joints. I just cannot see a need. The closest

is a dovetail joint, and I prefer doing these with hand tools. Still,

were I to make a box joint, the accessory of choice would be a linear

fence. These are easy-enough to build ...

Here is

an excellent video on YouTube building a linear fence

....

https://youtu.be/DCTmrLgaGVg

Regards

from Perth

Derek

February

2021